Why multi-physics simulation is vital for next-gen electric motors.

Electrification is accelerating a global industrial shift, with electric motors at its core. From EV powertrains and aerospace platforms to high‑precision robotics, today’s machines demand motors that deliver unprecedented torque density, efficiency, and long-term reliability.

The pressure to innovate within shrinking development windows—while still controlling cost—is unrelenting. Traditional “build‑and‑test” cycles can’t keep up; they’ve become a structural bottleneck rather than a path to progress. EMWorks, supported by HAH Software, replaces that constraint with a simulation-first workflow that accelerates design, reduces risk, and unlocks engineering agility.

Seamless CAD integration

EMWorks provides a high-fidelity simulation environment directly within your existing CAD platforms. This integration allows engineers to optimise electromechanical systems without the friction of platform-switching. With HAH Software providing local expertise across the UK and Ireland, teams don’t just get a tool; they gain a strategic partner in virtual prototyping.

Mastering the critical triad: Cost, weight and performance

The core advantage of EMWorks is the transition from reactive physical testing to proactive multi-physics simulation. By modelling the complex interplay of forces virtually, engineers can validate bold architectures long before committing to hardware.

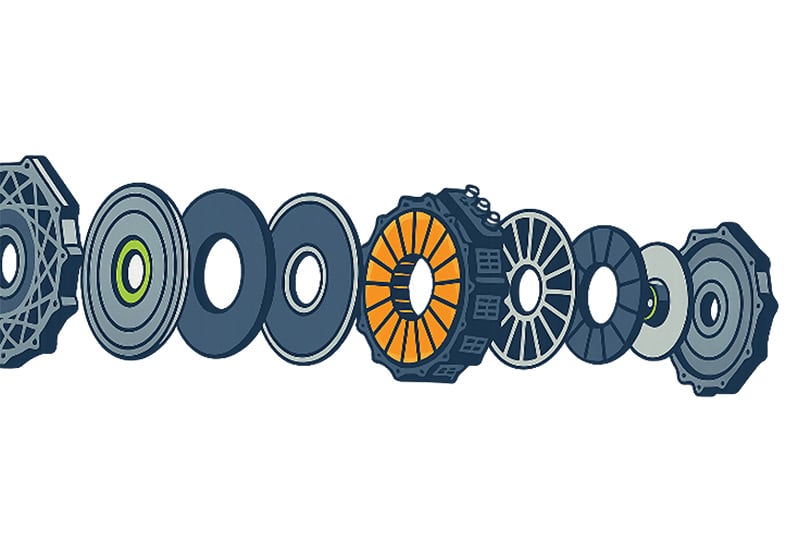

The platform’s depth covers the full spectrum of motor physics:

- Electromagnetic analysis: Use 3D finite element modelling to analyse magnetic flux, cogging torque, and inductance—essential for high-efficiency design.

- Thermal management: Simulate heat dissipation to prevent demagnetisation and ensure stable operation in compact, high-power housings.

- Structural integrity: Evaluate rotor-stator eccentricity and skewing to minimise noise, vibration, and harshness (NVH).

- Motion coupling: Bridge the gap between circuit behaviour and mechanical movement for a complete electro-mechanical profile.

Proven success across industries

From automotive teams optimising EV drive units to aerospace engineers validating UAV (Unmanned Aerial Vehicle) motors under extreme thermal stress, EMWorks is the common denominator in mission-critical design. Robotics designers utilise the platform to perfect smooth, precise motion, while industrial manufacturers benchmark rugged topologies for maximum durability.

The strategic edge

Beyond the lab, simulation-first design delivers a decisive market advantage. It shortens time-to-market, reduces the risk of field failures, and supports sustainability goals by optimising material usage.

As one engineering leader noted, EMWorks provides “real engineering agility” — the power to simulate the complex physics of electromagnetics, heat, and structural forces in a single, unified environment.

Lead the next wave of innovation

For organisations aiming to push the boundaries of motor performance, the path forward is clear.