Why simulation‑first is becoming the standard for efficient, safe, and scalable EV charging

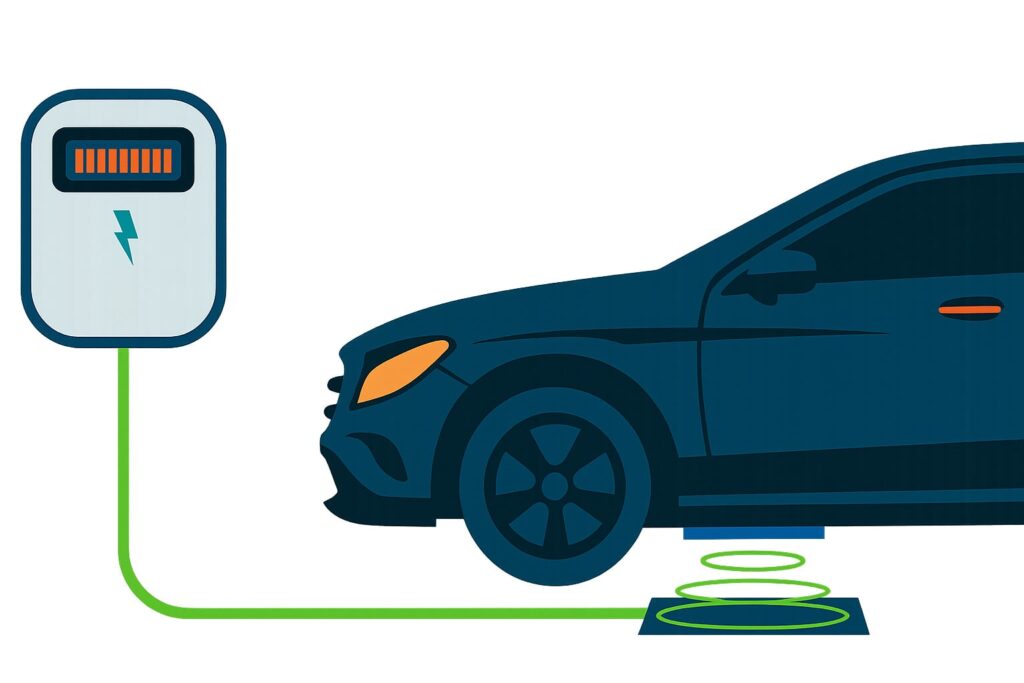

Wireless EV charging is rapidly shifting from a “nice-to-have” to an essential pillar of the electric mobility ecosystem. It offers many advantages: hands‑free energy transfer, reliable performance in all weather conditions, and the ability to support the autonomous EV fleets of the future

The engineering reality is a high‑stakes balancing act. Creating a charging pad that is efficient, safe, and scalable means contending with a tightly interlinked set of electromagnetic and thermal challenges — each one capable of undermining performance if not modelled with precision.

The challenge: The “ideal” vs the real world

At the heart of every system is the magnetic resonance between two coils — one in the ground, one on the vehicle. For peak energy transfer, these must maintain a tight electromagnetic coupling.

In the real world, “ideal” doesn’t exist. Engineers must account for:

- Variable air gaps: Different vehicle ride heights (SUVs vs coupés)

- Misalignment: Drivers rarely park with millimetre precision

- Thermal runaway: High-power transfer generates heat that can degrade components or trigger safety shut-offs

Why hardware-first is falling behind

Traditional development relies on physical prototypes. This “build-test-break” cycle is expensive, slow, and reactive. By the time a physical prototype reveals a thermal bottleneck or an EMI (Electromagnetic Interference) leak, weeks of development time and thousands of dollars have already been sunk.

The simulation advantage: Engineering with clarity

Simulation-first design flips the script. Using tools like EMWORKS, engineers can build a “digital twin” of the entire charging system. This allows teams to explore hundreds of variables long before a single piece of copper is wound.

Rapid iteration and performance optimisation

Engineers can virtually “swap” components in seconds to see how they impact the magnetic field:

- Test different ferrite layouts to direct flux more efficiently

- Compare litz wire specifications to minimise skin effect losses

- Evaluate aluminium shielding strategies to protect vehicle electronics

Compliance and safety are ensured

Wireless chargers must meet gruelling Electro-Magnetic Interference (EMI) and safety standards (such as the International Commission on Non-Ionizing Radiation Protection (ICNIRP) guidelines for human exposure). By modelling field leakage and harmonic behaviour early, you can validate compliance before committing to certification testing, drastically reducing project risk.

Data-driven material selection

The choice of insulation, copper grade, and structural housing affects the critical triad of EV design: cost, weight, and durability. Simulation allows you to benchmark materials and quantify trade-offs, ensuring the final product is commercially viable for mass production.

Lead the charge in EV innovation

Instead of reacting to failures late in the cycle, simulation allows engineers to anticipate and solve them upfront. It moves the industry from trial-and-error to precision engineering.

As EV adoption accelerates, the industry needs charging systems that are robust enough for mass deployment. Simulation is the key to unlocking that future.

If you’re developing wireless charging technology, it’s time to move from guesswork to engineered clarity. With EMWORKS and its UK and Ireland partner, HAH Software, you can master pad design, reduce development risk, and lead the next wave of mobility.

Master the future of EV charging. Register to receive your free design guide today.